Generator Rewinding Repair Services

Generator Rewinding Repair Services Specification

- Location

- Onsite

- Turnaround Time

- Typically 2-7 days depending on rating

- Repair Type

- Complete Overhaul, Coil Replacement, Insulation Rework

- Service Warranty

- Yes (Subject to Terms)

- Type Of Generator

- AC, DC

- Mode Of Service

- Offline

- Service Offered for

- Stator, Rotor, Armature, Field Coils

- Voltage Range Supported

- 110V to 11000V

- Generator Rating Supported

- Up to 2000 kVA

- Usage/Application

- Industrial, Commercial, Residential

- Winding Material

- Copper / Aluminium

- Testing Standard

- As per IS/IEC

- Service Mode

- Offline

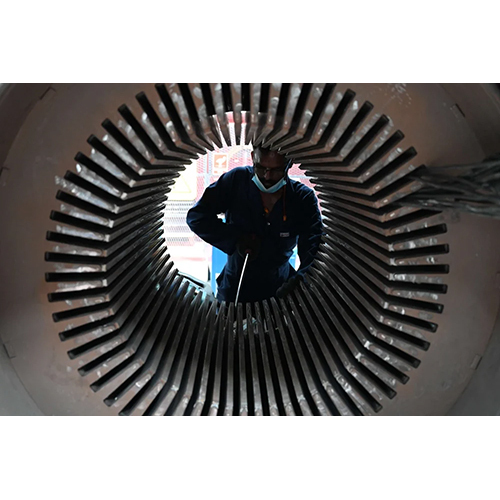

About Generator Rewinding Repair Services

Generator rewinding repair services involve restoring the motor windings in generators, ensuring efficient power generation and operational longevity. This service is crucial for industries like manufacturing, mining, and power plants, where generators are integral. Technicians follow strict safety regulations and use specialized tools like winding machines, insulation testers, and power analyzers. Skilled professionals, such as electrical engineers and certified technicians, handle rewinding tasks. The process enhances performance, reduces downtime, and extends generator life. Technologies like automated winding systems improve accuracy and speed. Compliance with electrical standards ensures safety and reliability in critical infrastructure and energy sectors.

Comprehensive Generator Rewinding & Repair

We offer complete generator overhauls, coil replacements, and insulation rework for a broad range of generator types and voltage requirements. Our expertise covers both copper and aluminium winding materials for generators up to 2000 kVA. All repairs are performed to rigorous IS/IEC standards, ensuring safety and long-term performance.

Efficient Onsite Service Across India

Our experienced technicians provide prompt onsite repair and rewinding services across the country. Whether your generator is installed in an industrial, commercial, or residential setting, we operate offline and adapt to your specific environment to minimize downtime and restore operation quickly-often within 2-7 days depending on generator rating.

Reliable Warranty and Testing

Every service is backed by a warranty (subject to terms) and includes comprehensive functional testing following IS/IEC standards. This ensures your generator is returned to optimal condition, delivering reliable performance and extending its operational life.

FAQ's of Generator Rewinding Repair Services:

Q: How is the generator rewinding repair process carried out?

A: Our process begins with a thorough inspection, followed by dismantling the stator, rotor, armature, or field coils as required. Old windings are removed, the core is cleaned, and new copper or aluminium windings are installed. After rewinding, the generator undergoes insulation rework, complete testing as per IS/IEC standards, and reassembly.Q: What types of generators do you service, and what is the supported voltage range?

A: We service both AC and DC generators used in industrial, commercial, and residential settings. Our services support generators with ratings up to 2000 kVA and voltage ranges from 110V to 11,000V.Q: When should I consider generator rewinding or repair services?

A: Consider our services if your generator experiences reduced efficiency, unusual noises, insulation breakdown, consistent tripping, or visible winding damage. Regular maintenance and rewinding can help prevent major breakdowns and extend the equipment's lifespan.Q: Where is the rewinding and repair service available?

A: We provide onsite repair and rewinding services across India for industrial, commercial, and residential applications. Our technicians reach your location to minimize disruption and downtime.Q: What are the benefits of using your generator rewinding repair service?

A: You gain from reduced downtime, extended generator life, improved efficiency, and cost-effective repairs. Our adherence to IS/IEC standards and comprehensive warranty provide peace of mind and reliable generator performance.Q: How long does the generator rewinding repair take?

A: The typical turnaround time ranges from 2 to 7 days, depending on the generator's rating and the extent of repairs required. We aim to restore your equipment with minimal disruption to your operations.Q: What kind of warranty and testing do you provide after repair?

A: All repairs come with a warranty (subject to terms) and undergo stringent testing in accordance with IS/IEC standards to ensure the generator is fully functional and safe for use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS