Wind Mill Generator Rewinding Repair Services

Wind Mill Generator Rewinding Repair Services Specification

- Repair Warranty

- 6 to 12 Months

- Phase

- Three Phase

- Usage/Application

- Wind Mill Generator

- Service Location

- On Site

- Cooling Type

- Air/Water Cooled

- Service Mode

- Offline

- Voltage Range Supported

- Up to 11 kV

- Response Time

- Within 24 hours of request

- Insulation Class

- Class F/H

- Winding Type

- Customized as per requirements

- Rotor Or Stator Rewinding

- Both Available

- Material

- Copper

- Service Type

- Wind Mill Generator Rewinding Repair Services

- Testing Provided

- Yes, Complete Functional Testing

- Power Source

- Electric

About Wind Mill Generator Rewinding Repair Services

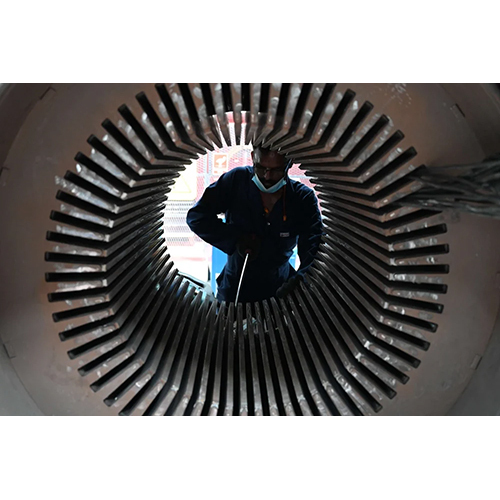

Windmill generator rewinding repair services involve restoring the windings of a wind turbine generator to ensure efficient energy production. This process is crucial for maintaining wind power systems, especially in renewable energy sectors. Advanced technologies, such as automated winding machines and precision testing equipment, are employed for quality repairs. The service is widely used in industries like renewable energy, power generation, and infrastructure. It helps reduce operational downtime, extend the lifespan of wind turbines, and improve energy efficiency. Rewinding repairs are vital for reducing maintenance costs and optimizing turbine performance for sustainable energy production.

Custom-Tailored Rewinding for Every Requirement

We understand that every wind mill generator presents unique operational challenges. That's why our rewinding and repair solutions are meticulously customized to align with specific voltage, insulation, and cooling requirements. Our engineers assess and address each project on-site, ensuring the rewinding process enhances longevity, reliability, and performance based on your application's exact needs.

Full-Service Support by Industry Experts

From diagnosis to rewinding and testing, our service covers all aspects of wind mill generator repair. Our skilled technicians provide both rotor and stator rewinding using premium copper materials and advanced insulation techniques. We ensure every repair meets Class F/H standards, and our complete functional testing guarantees readiness before generator hand-over.

Rapid Response and Reliable Warranty Coverage

We commit to reaching your site within 24 hours of your request, minimizing downtime for your wind mill generator. All repairs come with a warranty ranging from 6 to 12 months, giving you tangible assurance in our workmanship and materials. Our dedicated support team remains accessible throughout the service and warranty period.

FAQ's of Wind Mill Generator Rewinding Repair Services:

Q: How is the rewinding repair process carried out for wind mill generators?

A: Our rewinding repair process begins with a thorough diagnosis of your generator, followed by customized rewinding of either the rotor, stator, or both as required. We use high-quality copper wire, ensure insulation class F or H is applied as needed, and conduct full functional testing before returning the equipment to service.Q: What types of wind mill generators can you repair or rewind?

A: We service a broad range of three-phase wind mill generators operating up to 11 kV. Both air-cooled and water-cooled types are supported, and we offer rewinding for both rotor and stator components, adapting to specific customer requirements with our customized solutions.Q: When can I expect service after submitting a repair request?

A: We pride ourselves on rapid response, committing to provide on-site service within 24 hours of receiving your repair request, anywhere in India. This ensures minimal downtime for your wind mill operations.Q: Where does the rewinding and repair service take place?

A: All our rewinding and repair services are conducted directly at your site. Our team brings all necessary tools, materials, and testing equipment to ensure comprehensive, efficient repairs without the need to move your generator offsite.Q: What types of testing are performed after rewinding the generator?

A: Post-repair, we carry out complete functional testing to verify that the generator meets operational performance standards and safety regulations. This ensures reliability and helps prevent future breakdowns.Q: How does using insulation class F or H benefit my generator?

A: Applying insulation class F or H enhances the generator's resistance to high temperatures and electrical stress, extending its operational lifespan and improving safety during prolonged or demanding applications.Q: What warranty is offered on rewinding repair services, and what does it cover?

A: We provide a service warranty ranging from 6 to 12 months, covering workmanship and material quality. This assures you of reliable repairs and ongoing support should any issues arise within the warranty period.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS