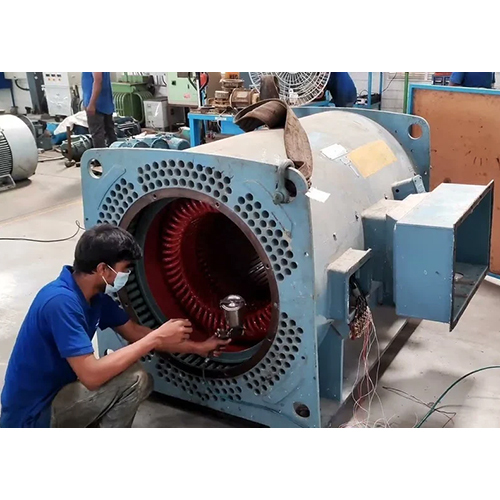

HT Motor Generator Rewinding Repair Services

HT Motor Generator Rewinding Repair Services Specification

- Testing Procedure

- Electrical Insulation, Megger, Surge, High Voltage, Load testing

- Pick-up and Delivery

- Arranged on request

- Type of Service

- HT Motor Generator Rewinding Repair Services

- Voltage Grade

- Upto 11KV (HT)

- Service Mode

- Manual/Mechanical depending on project

- Service Team Qualification

- Experienced & Skilled Technicians

- Equipment Handled

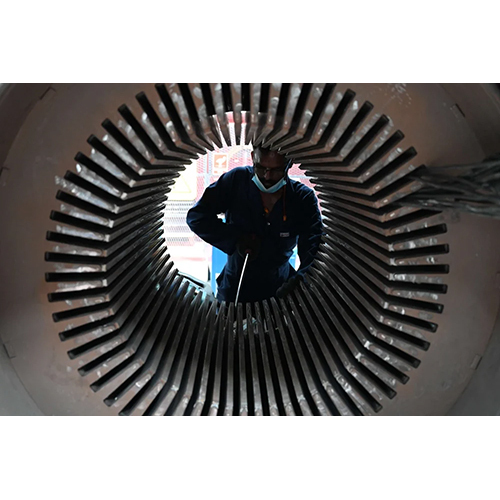

- Squirrel Cage, Slip Ring Motors, Turbo Generators

- Max Motor Capacity

- Up to 10 MW

- Suitable For

- High Tension Electric Motors & Generators

- Service Warranty

- Yes (Limited on rewinding work and insulation)

- Winding Material

- Copper/Aluminium (as per specification)

- Problem / Fault Coverage

- Burnt winding, insulation failure, noise, abnormal heating, reduced output

- After Service Support

- Available

- Insulation Class

- Class H/F/E as per requirement

- Service Quality Certification

- ISO 9001:2015 (where applicable)

- Duration

- As per machine condition and size

- Emergency Support

- Available

- Service Location

- On-site or Off-site (as required)

- Turnaround Time

- Quick response and completion as per customer need

About HT Motor Generator Rewinding Repair Services

HT motor generator rewinding repair services focus on restoring high-tension (HT) motors and generators, which are crucial for large-scale industrial operations. These services are essential in sectors like manufacturing, power generation, and oil & gas, where high-capacity machinery is used. The process involves specialized tools, such as high-voltage insulation testing equipment, automatic winding machines, and thermal curing systems. Adhering to safety rules and regulations, including IEC standards, ensures quality and reliability. Rewinding boosts motor efficiency, minimizes downtime, and extends equipment lifespan. This service is vital for maintaining smooth operations in critical industries, offering cost-effective, sustainable solutions.

Comprehensive Fault Coverage

Our services address a wide range of issues such as burnt windings, insulation failure, excessive noise, abnormal heating, and reduced machine output. We use advanced testing procedures-Electrical Insulation, Megger, Surge, High Voltage, and Load Testing-to pinpoint and resolve faults effectively, ensuring reliability and extended equipment lifespan.

Skilled Experts and Quality Assurance

Experienced technicians implement state-of-the-art rewinding and repair procedures, adhering to ISO 9001:2015 quality standards. Whether manual or mechanical intervention is required, our team ensures that each machine is restored to optimum functionality with a service warranty covering rewinding and insulation work.

Flexible Service Modes and Fast Turnaround

We deliver quick response times and adapt our service duration to match the specific machine condition and customer urgency. Depending on the project requirements, repairs can be performed on-site or off-site, with pick-up and delivery options available to maximize convenience. We also provide emergency support for urgent cases.

FAQ's of HT Motor Generator Rewinding Repair Services:

Q: How do I request HT Motor Generator rewinding repair services and what is the typical process?

A: To request services, you can contact us directly as a manufacturer, supplier, or service provider. After initial assessment, our team arranges inspection and testing, provides a quotation, and upon approval, performs rewinding and repairs either on-site or off-site as per your preference. Testing and validation are done before the machine is returned or recommissioned.Q: What types of motors and generators can you service and up to what capacity?

A: We handle squirrel cage motors, slip ring motors, and turbo generators with capacities up to 10 MW. Both copper and aluminium winding materials are supported for HT motors and generators with voltage grades up to 11KV.Q: What quality certifications and service warranty do you provide for your repair work?

A: Our service adheres to ISO 9001:2015 quality standards (where applicable). Warranty is provided for rewinding and insulation work, ensuring reliability and peace of mind to customers.Q: When can I expect my repaired motor or generator to be ready?

A: Turnaround times depend on machine condition and size, but we prioritize quick response and completion as per the customer's need. Emergency support is available for urgent cases, and pick-up/delivery can be arranged on request to further expedite the process.Q: Where are the repair services conducted and what after-service support is available?

A: Repairs are carried out either on-site at your location or off-site as required. After-service support is available to address any queries or issues post-repair, ensuring sustained operational efficiency for your equipment.Q: What testing procedures are conducted following the rewinding or repair?

A: Post-repair, we conduct thorough testing including electrical insulation checks, Megger tests, surge tests, high voltage assessments, and load testing. This ensures the repaired equipment meets performance standards and operates safely and efficiently.Q: What are the main benefits of using your HT Motor Generator Rewinding Repair Services?

A: You benefit from expert repairs with certified technicians, comprehensive fault coverage, service warranty, rapid turnaround, emergency support, and flexible logistics-all tailored for high-tension electric motors and generators up to 11KV and 10 MW.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS