Chiller Motor Rewinding Services

Chiller Motor Rewinding Services Specification

- Service Mode

- Offline

- Application Area

- Chiller Motor

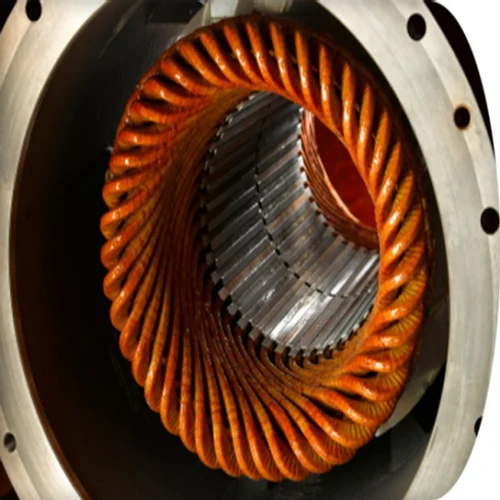

- Winding Type

- Double Layer Lap

- Frequency

- 50-60Hz

- Motor Power Range

- Up to 100HP

- Product Name

- Chiller Motor Rewinding Services

- Voltage Rating

- Up to 415V

- Testing Included

- Insulation Resistance & No Load Test

- Service Warranty

- 3 to 6 Months

- Material Used

- High Quality Copper Wire

- Type of Service

- Motor Rewinding

About Chiller Motor Rewinding Services

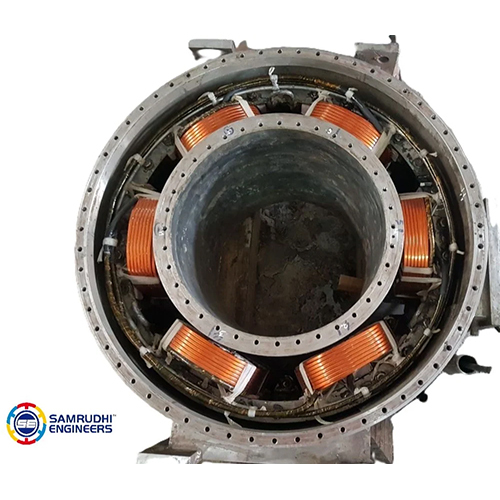

Chiller Motor Rewinding is the meticulous art of restoring a chiller's vital heartbeat - its electric motor. This intricate process, governed by stringent safety and environmental regulations, involves skilled electricians and motor rewinders armed with advanced techniques and specialized machinery. From diagnosing the root cause of motor failure to precisely rewinding coils and employing vacuum pressure impregnation for optimal insulation, the goal is to breathe new life into the motor. This not only extends its lifespan but also enhances energy efficiency, minimizes downtime, and significantly reduces operational costs across diverse industries like food processing, pharmaceuticals, and data centers.

Expert Motor Rewinding for Chiller Applications

Our chiller motor rewinding services cater specifically to chiller applications, offering a tailored approach for motors up to 100HP. With extensive experience in both manufacturing and service provision, our team guarantees precise rewinding using premium-grade copper wire for sustained performance.

Rigorous Testing for Reliable Performance

Each rewinding project includes both insulation resistance and no-load tests, ensuring your motor operates efficiently and safely. These comprehensive checks help identify potential issues early, delivering peace of mind and reliable operation for your chiller system after the rewinding process.

FAQ's of Chiller Motor Rewinding Services:

Q: How is the chiller motor rewinding process carried out?

A: The rewinding process begins by dismantling the motor and removing old winding materials. High-quality copper wire is then used to execute double layer lap winding as per the motor's specifications. After winding, insulation resistance and no-load tests are conducted to ensure safety and reliability before reassembly.Q: What materials are used in the rewinding service?

A: Only high-grade copper wire is utilized for rewinding, which offers superior conductivity and durability. All materials comply with industry standards to guarantee long-lasting motor performance.Q: When should I consider rewinding my chiller motor?

A: Rewinding should be considered if the motor exhibits reduced efficiency, overheating, burning smell, or if electrical faults like insulation failure are detected. Routine testing can also indicate the need for rewinding before complete breakdown occurs.Q: Where is this service available, and how can I access it?

A: Chiller Motor Rewinding Services are available across India. As a leading manufacturer, supplier, and service provider, you can contact us offline to schedule inspection, transport, and service for your chiller motor.Q: What is the benefit of using double layer lap winding in motor rewinding?

A: Double layer lap winding enhances current distribution, minimizes losses, and supports higher power loads up to 100HP. This method increases the motor's reliability and extends its operational life.Q: Is warranty and testing included as part of the service?

A: Yes, all rewinding services come with a warranty period between 3 to 6 months. Comprehensive insulation resistance and no-load tests are included to ensure the rewound motor's performance and safety before returning it to service.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS