EMS Coil Rewinding Services

EMS Coil Rewinding Services Specification

- Winding Technique

- Manual/Automatic

- Emergency Service

- Offered

- Duration

- As per Requirement

- Service Warranty

- Yes

- Service Mode

- Offline

- Coil Type

- EMS Coil

- Quality Assurance

- Tested for continuity and insulation resistance

- Service Type

- Coil Rewinding Service

- Material Used

- Copper or Aluminum

- Expertise

- Handled by experienced professionals

- Application

- Industrial, Transformer, Electric Motor

- Pickup and Delivery

- Available on request

- Frequency Range

- 50-60 Hz

- Voltage Support

- Up to client specification

- Phase

- Single/Three Phase

- Customization

- Available as per drawing/sample

- Minimum Order Quantity

- 1 piece

- Location

- All Over India

About EMS Coil Rewinding Services

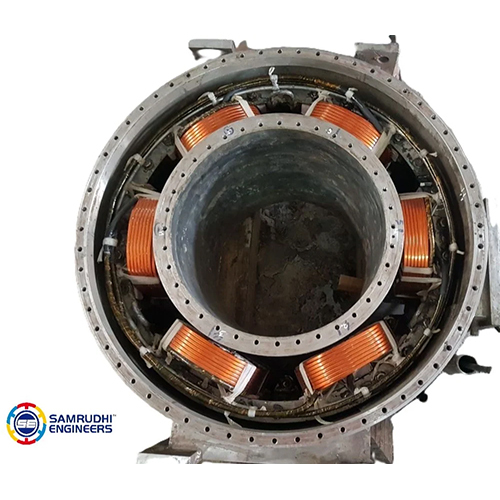

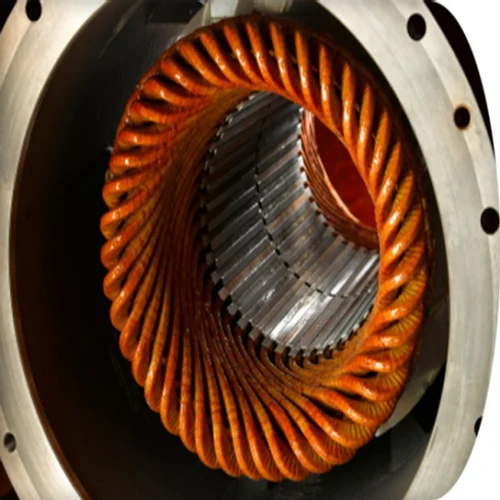

The specialised service of repairing or rebuilding the vital electrical coils in Electro-Mechanical Systems (EMS) is known as EMS Coil Rewinding. This complex procedure necessitates careful workmanship from qualified technicians and engineers and is regulated by stringent safety and quality control regulations. EMS Coil Rewinding repairs broken coils in motors, generators, transformers, and other essential parts by using sophisticated winding procedures, accurate measurements, and specialised equipment such winding machines and insulation testers. In a variety of industries, including manufacturing, transportation, and power production, this not only prolongs the life of pricey equipment but also improves efficiency, lowers energy consumption, and minimises costly downtime.

Expert EMS Coil Rewinding Solutions

Experience reliable and precise coil rewinding for industrial applications, including transformers and electric motors. Our skilled team utilizes both manual and automatic winding techniques using high-grade copper or aluminum, maintaining strict quality assurance. Each coil undergoes continuity and insulation resistance testing to guarantee performance and safety.

Customizable Service Tailored to Your Needs

Clients benefit from complete customization based on drawings or samples to ensure the rewound coils meet unique operational demands. Voltage, frequency, and phase specifications are accommodated according to your requirements, supporting both single and three-phase systems.

Dedicated Support and Comprehensive Coverage

Enjoy peace of mind with our service warranty, emergency response options, and nationwide pickup and delivery service. Our flexible service duration adapts to your project timelines, supported by knowledgeable professionals in both manufacturer and supplier roles.

FAQ's of EMS Coil Rewinding Services:

Q: How is the EMS coil rewinding process carried out?

A: Coil rewinding is performed using either manual or automatic winding techniques, based on the coil's requirements and your preferences. Our specialists strip the old winding, inspect the core, and rewind with high-quality copper or aluminum, followed by comprehensive testing for insulation and continuity.Q: What types of materials are used for coil rewinding?

A: We use premium-grade copper or aluminum for rewinding, selected to match application requirements and ensure optimal performance and longevity of the rewound coils.Q: When can I request emergency EMS coil rewinding services?

A: Emergency rewinding support is available upon request. Contact us any time your machinery or equipment needs urgent coil maintenance, and our team will prioritize your service to minimize downtime.Q: Where are EMS coil rewinding services available?

A: Our coil rewinding services are offered across India, with pickup and delivery options available nationwide to provide maximum convenience.Q: What is the benefit of choosing a professional coil rewinding service?

A: Professional rewinding ensures precision workmanship, strict quality control, material traceability, and reliable operation, reducing risks of device failure and prolonging equipment life.Q: How can I customize my rewinding service to fit my requirements?

A: Simply provide your technical drawing or a coil sample, and our team will tailor the winding technique, material, voltage support, and phase options to meet your specific operational needs.Q: What guarantee is provided with coil rewinding services?

A: All rewound coils are backed by a service warranty and thorough quality tests, including insulation resistance and continuity checks, to ensure reliable performance and client satisfaction.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS