HT Motor Generator Rewinding Service

HT Motor Generator Rewinding Service Specification

- Application

- Industrial, Power Plants, Cement, Steel & Sugar Mills

- Frequency

- 50 Hz

- Service Provided By

- Qualified Engineers and Technicians

- Service Type

- HT Motor Generator Rewinding Service

- Phase

- Three Phase

- Downtime Minimization

- 24x7 Service Support

- Rewinding Technique

- VPI (Vacuum Pressure Impregnation) available

- Voltage

- Up to 11 KV

- Insulation Class

- Class F or Class H as per requirement

- Supported Brands

- All major HT motor & generator brands

- Testing Provided

- Insulation Resistance, Surge Test, No Load Test

- Winding Material

- Copper

- Service Mode

- Offline & On Site

- Motor Type

- High Tension (HT) Motor & Generator

About HT Motor Generator Rewinding Service

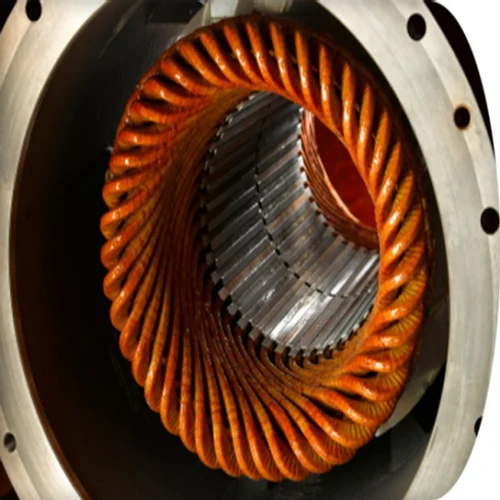

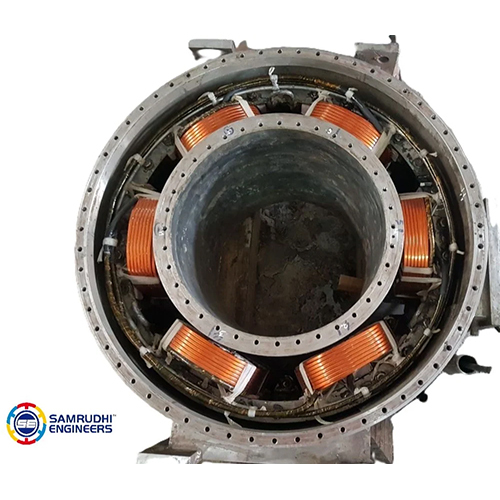

HT Motor Generator Rewinding Service involves repairing and refurbishing high-tension (HT) motors and generators by rewinding their stator and rotor coils. This service is essential for maintaining efficiency in industries like power plants, steel mills, and manufacturing. Professionals, including skilled technicians and engineers, use advanced tools, such as winding machines and insulation testers, ensuring compliance with safety regulations. Rewinding enhances motor lifespan, reduces downtime, and improves energy efficiency. It's crucial in sectors like mining, manufacturing, and utilities. The service follows specific design standards to ensure quality, performance, and safety, benefiting businesses by minimizing operational costs and enhancing machinery longevity.

Expertise in HT Motor Generator Rewinding

Our team comprises skilled engineers and technicians experienced in rewinding HT motors and generators for various industries. Each rewinding service is conducted using proven techniques and premium copper winding materials, ensuring durability and high performance. We adhere to standard practices, delivering service for insulation classes F or H depending on your needs.

Comprehensive Testing and Quality Assurance

Alongside the rewinding process, our service includes rigorous testing such as insulation resistance, surge, and no-load tests. These assessments ensure the reliability and safety of your HT motors and generators before they are returned to service. Our commitment to quality helps minimize unexpected failures and ensures operational efficiency.

Minimizing Downtime with 24x7 Support

To keep your operations running smoothly, we provide round-the-clock support. Our service is available both off-site at our facility and on-site at your location, reducing transportation time and downtime. We prioritize rapid turnaround and efficient troubleshooting so your equipment is back in operation as quickly as possible.

FAQ's of HT Motor Generator Rewinding Service:

Q: How is your HT Motor Generator rewinding process different from standard methods?

A: We utilize Vacuum Pressure Impregnation (VPI) during the rewinding process, which ensures deeper penetration of insulating materials, improving winding durability and extending motor or generator life. All procedures are carried out by certified engineers and technicians using high-quality copper and insulation conforming to class F or H as needed.Q: What types of industries benefit most from your rewinding services?

A: Our rewinding service is ideal for power plants, cement, steel, and sugar mills, as well as any industry relying on HT motors and generators for critical operations. We support equipment from all leading brands, ensuring versatility and broad compatibility.Q: When can I access your HT rewinding services and how do you minimize downtime?

A: Our services are available 24x7, with both off-site and on-site solutions depending on what suits your operation best. By offering rapid response and expert troubleshooting, we help minimize downtime so your systems remain operational and efficient.Q: Where do you provide your rewinding services?

A: We offer our rewinding services across India, either at our specialized facility or directly at your site. This flexible approach accommodates the needs of clients who require immediate and local support.Q: What tests do you perform after rewinding, and why are they important?

A: Post-rewinding, we conduct insulation resistance, surge, and no-load tests. These critical assessments verify the safety, performance, and reliability of the rewound HT motors/generators, ensuring they are fit for service before reintegration into your operations.Q: Which brands and motor types do you support for rewinding?

A: We cater to all major HT motor and generator brands, focusing on three-phase, high-tension electrical machines with voltages up to 11 KV and running at 50 Hz. Our expertise covers a broad spectrum of industrial equipment.Q: What are the key benefits of using your HT rewinding service?

A: Clients benefit from enhanced motor/generator lifespan, reduced risk of breakdowns, rapid turnaround, certified workmanship, rigorous testing, and robust after-service support, all designed to optimize industrial productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS